Although the project originally started as a facade panel concept for a much larger project, this small art commission became an in-depth exploration of computational processes and fabrication techniques. Each of the thirty-six tiles is the result of a very specific set of operations related to two-dimensional shape cutting and three-dimensional bending.

In the fabrication of a typical facade cassette panel, notches are cut from the corners of a rectangular piece of sheet metal to allow it to be folded into a five-sided box. The starting point for this project was to explore what it would mean if those corner cutouts were not all equal in size. By making some of the cutouts larger than others, the result of a folding operation is no longer a rectangular cassette panel, but a more complicated and irregular quadrilateral shape that won’t sit flat.

The problem with irregular panel shapes, of course, is that they don’t fit together nicely into a rectangular frame. Yet using a set of custom-coded heuristics and search algorithms, it was discovered that the resultant set panels made by a finite number of cutting and folding operations could (with a degree of tolerance) be fit together to form a rectangle. In fact, solutions to this seemingly difficult problem were not that rare. So another set of digital tools were created to allow the designer to sift through the possibilities in search of more subjective qualities relating to complex symmetries and three-dimensional bending.

Fabricating the piece was a of particular interest, because, although the panels themselves were laser cut and fabricated to exacting dimensions, they did not take their final shape until they were drawn back and bolted to a laser cut backer plate. Several mockups were made to refine this decidedly analog portion of the project prior to sending the final panel files to the laser cutter. At every point in the transition from computer to finished piece, the continued input from the experienced metalworkers at Caliper Fabrication was an invaluable resource.

Although many studies were done in a less reflective material , for the final piece the panels were made of prefinished polished stainless steel. A protective film was kept on the panels during the entire shop fabrication process and the full impact of the torqued reflections was only revealed when the project was unveiled onsite.

The Reflective Tiled Sculpture sits in a niche in a private courtyard directly facing a large living room window. In this way, the sculpture is constantly on view from the interior spaces.

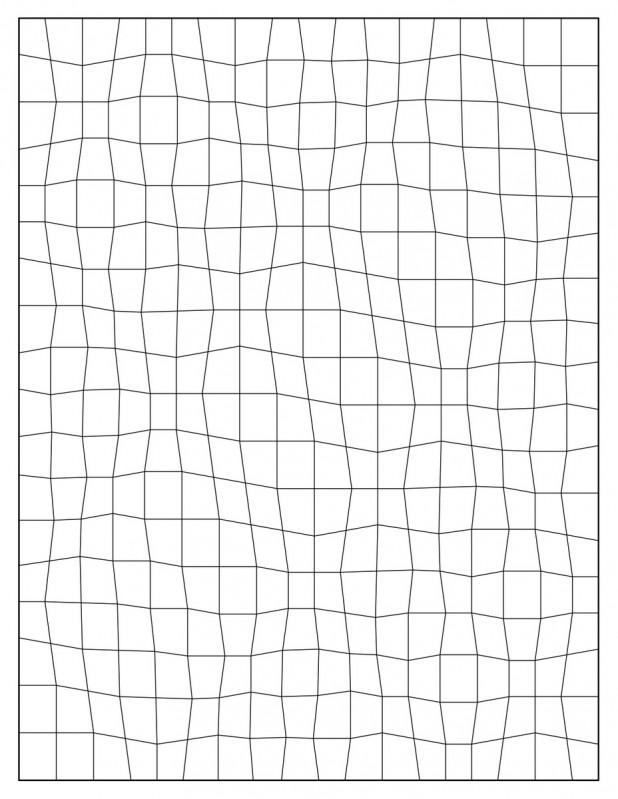

This animation is a visualization of the “depth first” search algorithm employed to find viable solutions to the puzzle of fitting a finite set of irregular panels into a given rectangular opening.

Solutions to the seemingly difficult problem of fitting irregular tiles into a rectangular shape necessitated a set of digital tools allowing the designer to sift through the possibilities in search of more subjective qualities relating to complex symmetries and three-dimensional bending.

The task of finding workable configurations becomes much more computationally intensive as the field grows. To find a single configuration like the one shown here can require hours rather than minutes.

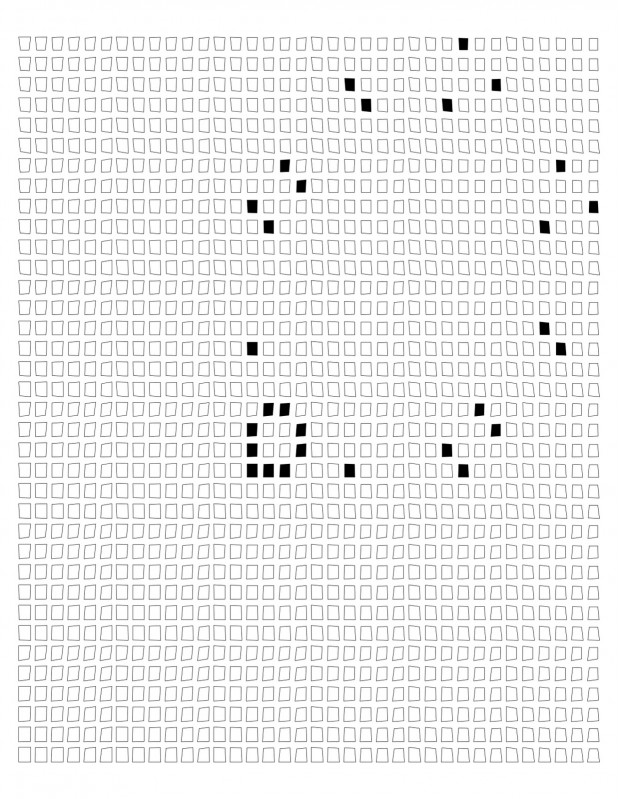

Diagram showing 1296 possible panel types using six different corner cuts. Shown in black are the panels that can be fit together to form one thirty-six panel rectangular configuration.

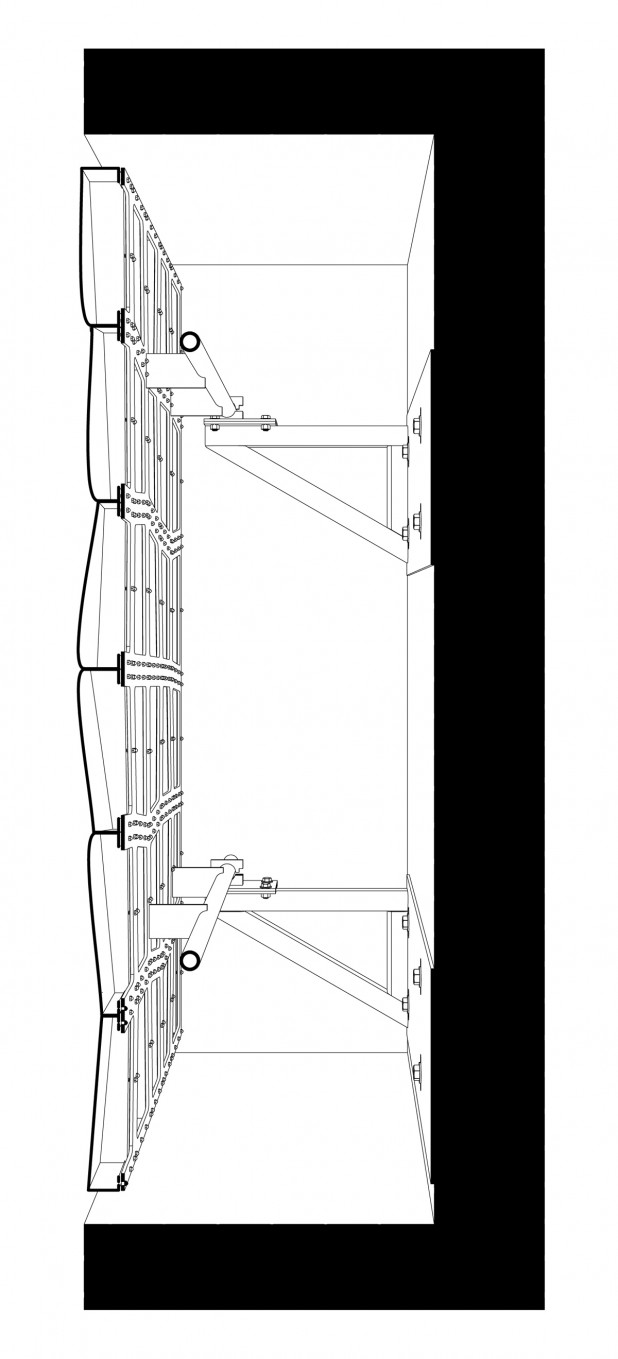

One of the most important constraints for the algorithmic design process was the size of the niche in the existing brick wall.

This drawing shows the mounting mechanism for the pieces. First the thirty-six folded panels were drawn back against a precisely calibrated backer plate and then the whole assembly was hung on brackets sized to bring the face of the sculpture just proud of the existing brick wall.